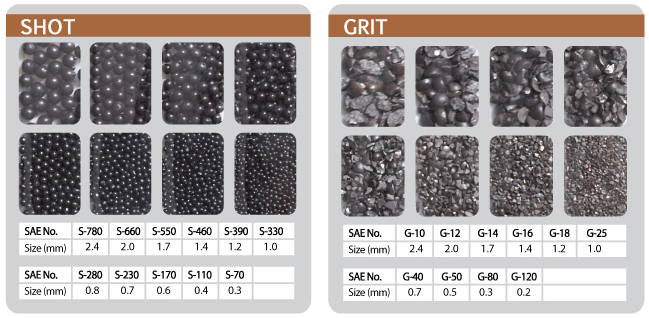

Steel shot & steel grit are two different shapes of steel abrasives each of which are suitable for different types of industrial applications. Steel shot is spherical widely used abrasive for stripping & cleaning metal surfaces producing

smooth polished finishes.

Steel grit is an angular shaped abrasive used for aggressive cleaning and stripping of steel and foundry metals. Its angular shape produces an etching on hard metals which provides better adhesion for coatings including paints, epoxy, enamel and rubber.

Rock Garnet Trading represents one of the biggest factories in Korea producing various steel shot balls and steel grit. All products are manufactured by a fully automatic system under strict inspection and supervision.

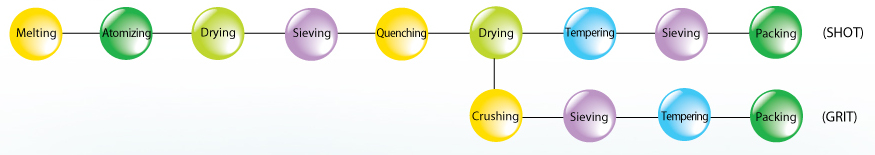

Process

Steel shot & steel grit have similar manufacturing processes.

Chemical Analysis

| Carbon | 0.85 ~ 1.20% |

| Silicon | 0.40 ~ 1.50% |

| Sulphur | 0 ~ 0.50% |

| Phosporous | 0 ~ 0.50% |

| Manganese | 0.35 ~ 1.20% (S-70, S-110) 0.50 ~ 1.20% (S-170) 0.65 ~ 1.20% (S-230 and above) |

Recommended Applications

Steel Shot

| Cleaning | HRC 40 ~ 50 | Sand removal of cast iron, surface blast cleaning |

| Descaling | HRC 40 ~ 50 | Scale removal of steel plates and steel structures |

| Peening | HRC 45 ~ 55 | Surface treatment of gears and springs |

Steel Grit

| Cleaning (SG) | HRC 40 ~ 50 | Sand removal of cast iron, surface blast cleaning |

| Descaling (LG) | HRC 55 ~ 60 | Scale removal of steel plates and steel structures |

| Peening (HG) | HRC 62 ~ 67 | Surface treatment of gears and springs |